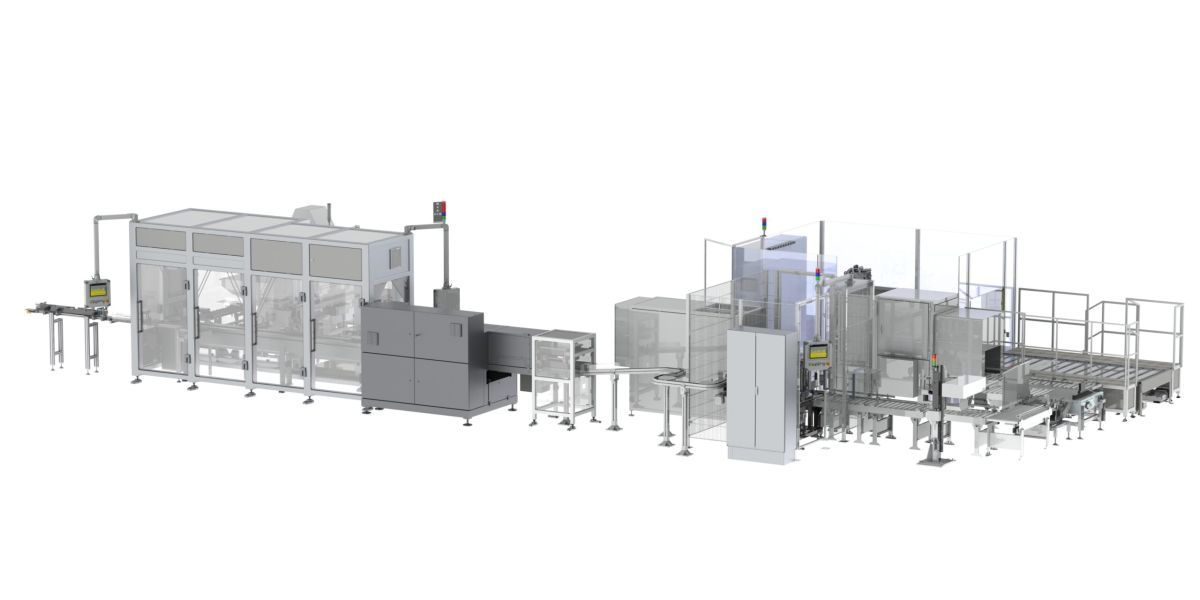

Packaging lines for bonded anchors

Primary/secondary packaging + palletizing

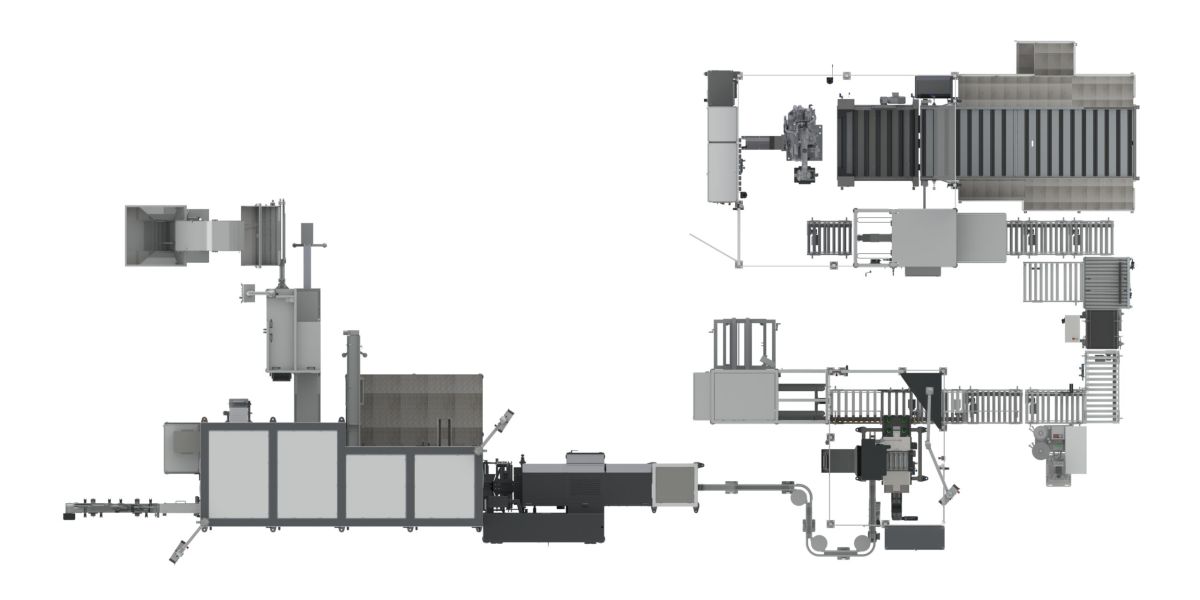

The packaging plant depicted shows the primary and secondary packaging of bonded anchors, incl. the following palletizing. Cartridges which arrive in-line from the assembly plant are inserted into the conveyor belt of a tubular bag machine. Depending on the format/product, each compartment will be completed with different additional components, e.g. blenders and instructions, in the further stations of the picker line. These blenders are – coming from the bulk material – fed under automated quality control. Instructions are counter-checked by means of a QR-code and scanner and fed by means of a friction feeder. In the tubular bag machine, the film will first be printed individually and then sealed by sealing devices at the longitudinal seam and the cross seams.

In the subsequent secondary packaging, tubular bags are collected in a grouping station and grouped as complete package contents by means of lift table. The station is made in a way that even asymmetric packing patterns can be produced. As the erection and closing of a shipping carton happens at standardized adhesive tape aggregates, the cardboard box is swivelled by 90° for loading, and then the complete product group is pushed into the carton (Fefco 0201). As a consequence, the tubular bags are aligned in upright position in the shipping carton later on.

In the further process, a label is applied by means of a printing and dispensing unit and the cardboard box is checked for completeness by a control scale with outward transfer.

The cardboard boxes are stacked onto pallets at the last part of the plant by regarding the carton format and its pallet pattern. Empty pallets are brought in via on-site provided FTS systems, and loaded pallets are accepted. The pallet exchange within the plant is fully automatic.

- in the fields of food, pharmaceuticals, personal care, industry

- primary/secondary packaging/palletizing

- packaging of several different components in a packaging unit

- operations in connection with existing machines or as comprehensive package

- packaging in connection with tubular bags, top load boxes, side load boxes, box cases, thermoformed trays, blisters, etc.

- for single as well as multi- format operations

- automated format change

- automated gripper exchange

- component monitoring per RFID

- monitored line clearance

- versions according to industry-specific requirements for the primary packaging sector

- additional camera systems for quality control

- additional product/box transport belts

- additional provision as product store

- grouping incoming multi-varietal into mono-varietal products

- creation of assorted packages

- flap locking with hot glue

- bottom/intermediate/cover layers on pallets

- provision of several pallet types at the same time

(project-specific)

- up to 50 tubular bags/min

(higher performance by technical adjustment possible) - primary packaging in tubular bags

- product and tubular bag flow into same direction

- automatic separation of bulk material or from stack

- counterchecks during insertion

- film printing

- outward transfer with sample controls

- secondary packaging in shipping cartons

- carton type American Case (Fefco 0201)

- flap lock with adhesive tape

- product insertion into swivelled cardboard box

- printing and dispensing unit for application of labels

- check for completeness via control scale

- palletizing

- on Euro and US pallets

- automatic pallet exchange

- pallet feed/removal via on-site FTS- systems

- maximum compact design

- 2-pallets buffer spaces each

Our life is technology.

We will be happy to assist you.

Goldfuß engineering GmbH

Am Bangraben 12

72336 Balingen, Germany

Phone: + 49 [0] 7433 / 996599-0

Fax: +49 [0] 7433 / 996599-50

Email: [email protected]