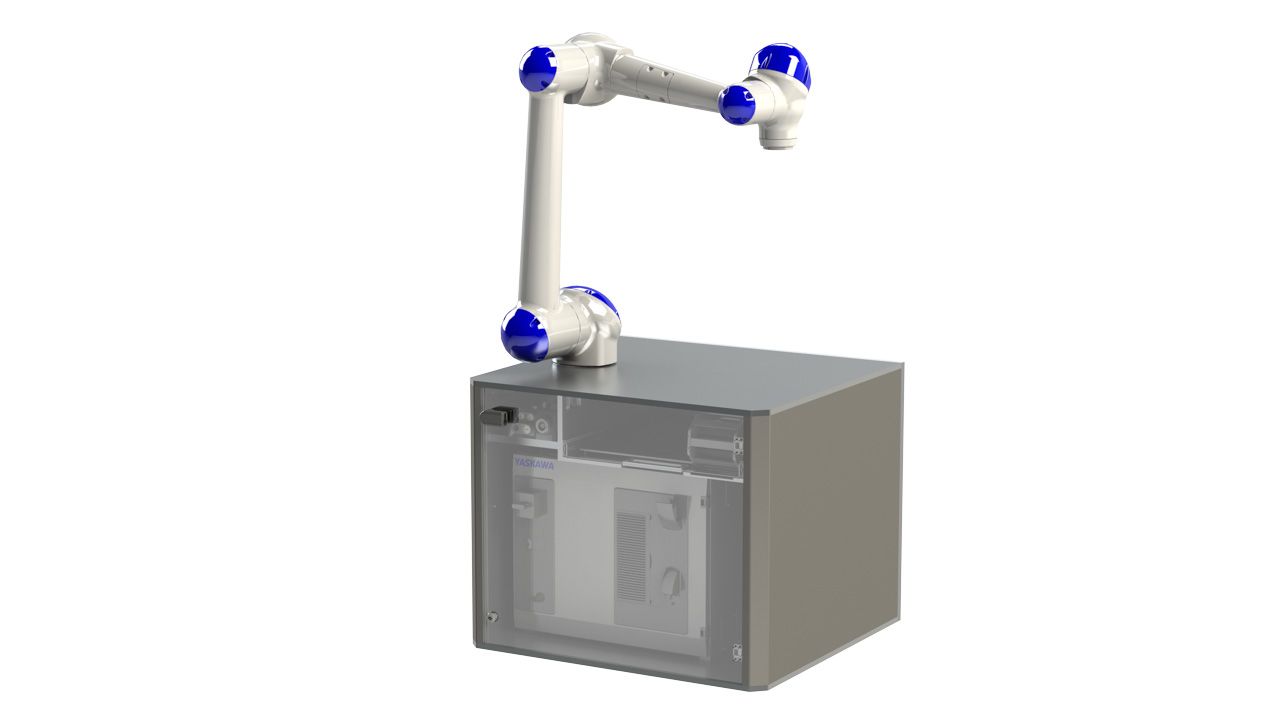

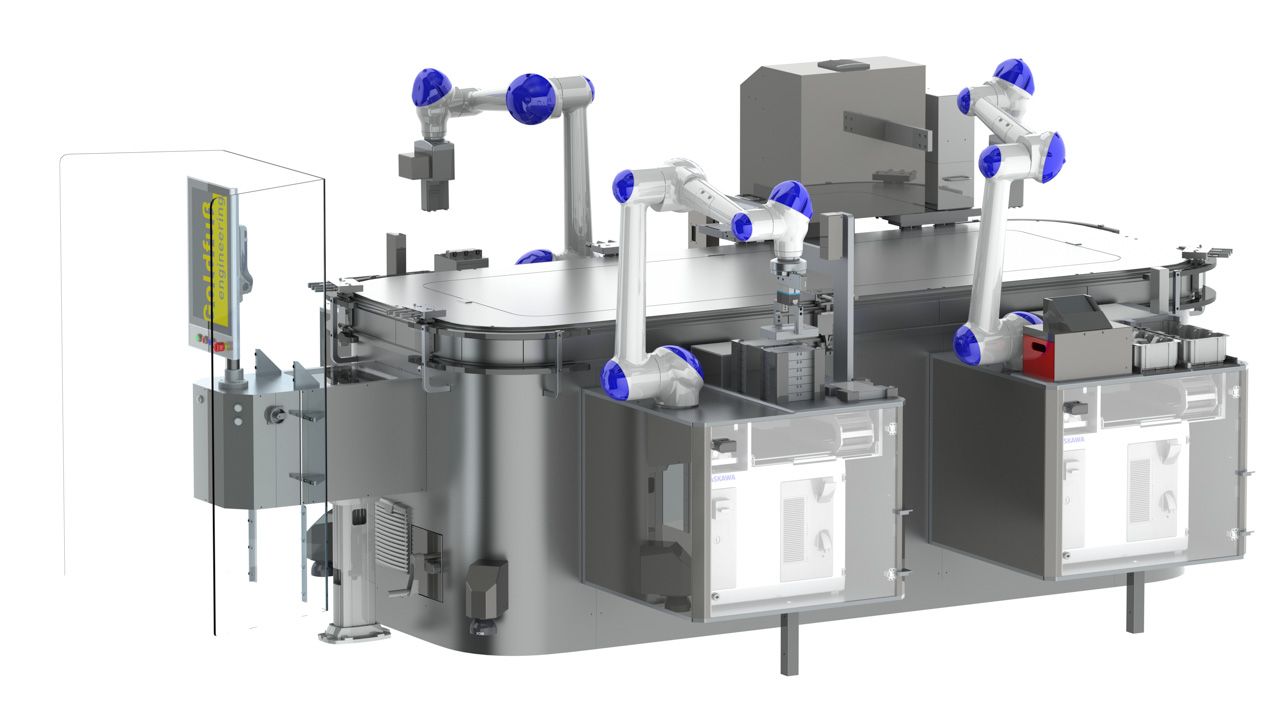

Feeding systems with cobot

All feeding systems can be equipped with “collaborating“ robot technology. Depending on the application, the gripper technology, the other periphery and the movement speed, the environmental area needs to be supervised by ground scanners which allow “coexistent“ operations.

Adjacent areas for walking/driving can be separated by mechanical barriers on requirement.

Unpacking/feeding processes can be executed in single stations as well as with several robots in cooperation. Shuttle systems connect the single stations and offer various possibilities from product tracking via RFID to on-the-fly format change.

- pharmaceutical industry

- for minimal batches

- secondary packaging

- subsequent individual printing

- for single and multi format operations

- centrally integrated switch cabinet

- AMR connection

- format change on-the-fly

- component monitoring per RFID

- serialization

- packaging material control via code scanner

- monitored line clearance

- up to 15 cycles/min

- automated format change

- feeding of printers, labellers, inspection machines, packaging machines, etc.

- cell size depending on application

- operations without mech. safety housing (coexistent operations)

You are currently seeing a placeholder content of YouTube. To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

Further informationOur life is technology.

We will be happy to assist you.

Goldfuß engineering GmbH

Am Bangraben 12

72336 Balingen, Germany

Phone: + 49 [0] 7433 / 996599-0

Fax: +49 [0] 7433 / 996599-50

Email: kontakt@goldfuss-engineering.com