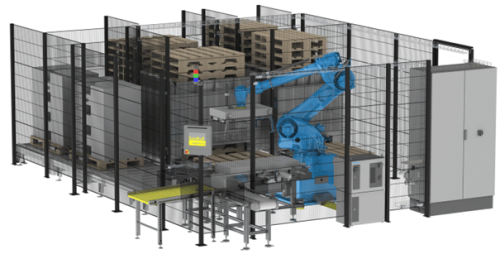

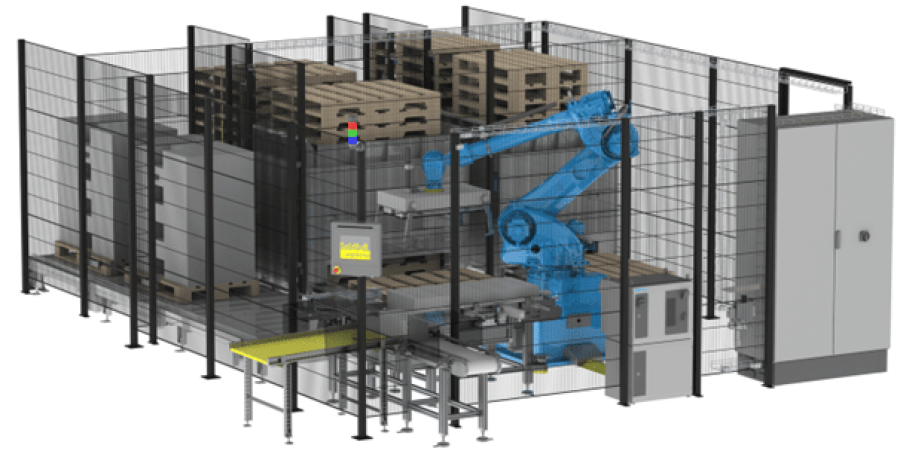

Palletizing cell

The palletizing cell is provided for stacking cartons or stable products/containers according to a given layer formation.

The feeder belt can be placed in work height or in passage height of 2000mm, according to your requirements.

Due to the application of a 6-axis robot, the gripper can be swivelled, and nearly each orientation of the carton/product during the layer formation is enabled.

A palletizing software grants a quick and simple creation of new pallet patterns.

To grant an uninterrupted production or to add intermediate layers, several pallet spaces or automatic pallet exchange are possible.

- in all industries

- as a compact single cell for the completion of semi-automated stand-alone solutions

- central palletizing with operation of several pallet spaces and outgoing lines

- for re-palletizing in logistics centres or in the co-packaging field

- palletizing software for creation of pallet patterns

- up to 15 loading cycles/min with 1 robot

- quantity of cardboard boxes per loading cycle depending on box size and packing pattern

- repeatability: 0.1 mm

- format change in the minute range

- pre-grouping of cardboard boxes/products

- cell size depending on application and product -/box size

- industry-specific and individually matched gripper systems with vacuum, clamp gripping or downside gripping

- bottom/intermediate/upper layers

- automatic pallet exchange

- automatic feeding of empty intermediate layer pallets

- magazine for empty pallets

- provision of several pallet types at the same time

- palletizing of several rows in parallel

- format change reduced to recipe change only

- automated gripper exchange

- component monitoring per RFID

- monitored line clearance

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationOur life is technology.

We will be happy to assist you.

Goldfuß engineering GmbH

Am Bangraben 12

72336 Balingen, Germany

Phone: + 49 [0] 7433 / 996599-0

Fax: +49 [0] 7433 / 996599-50

Email: [email protected]