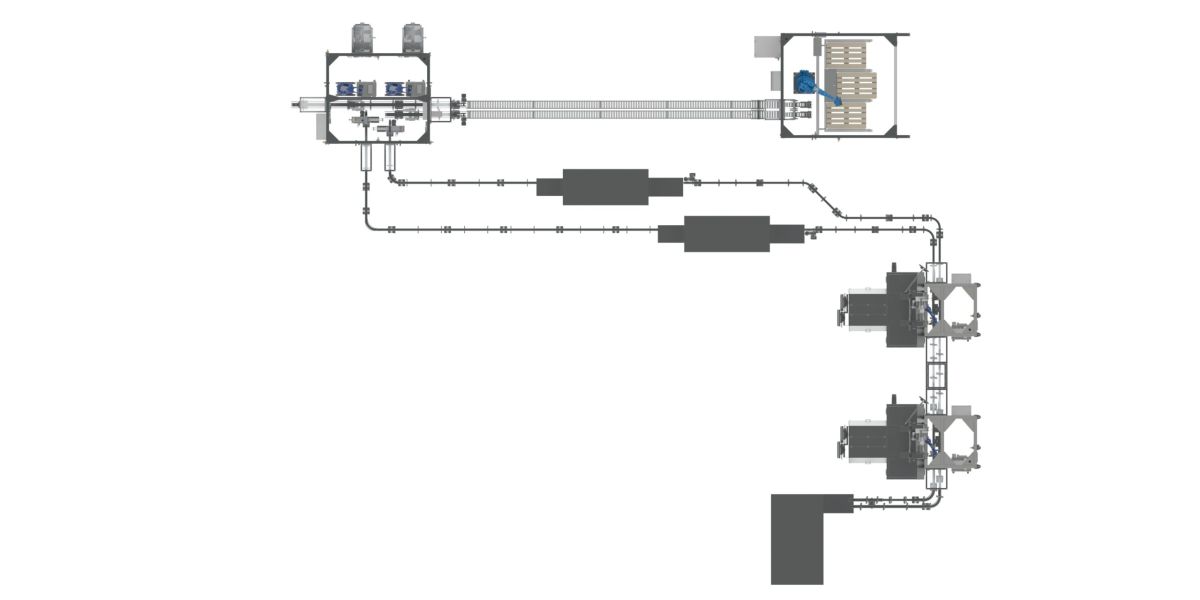

Packaging line for organic bags

Primary/secondary packaging + palletizing

The packaging plant here depicts the primary and secondary packaging for organic bags, incl. the following palletizing. Coreless winded rolls are directly taken from two winding systems and placed in top load boxes that have been erected before. Robot-assisted gripper technology ensures that the rolls do not unwind during removal. The winding systems can process similar or different bag formats.

During the following secondary packaging, the loaded and closed boxes are collected in two grouping stations and inserted into the carton tray. The erection of trays (automatic bottom/carton boxes) is executed by the same robot and gripper that also loads the boxes.

Due to its two-line design, the plant can run two different formats at the same time.

In the last part of the plant the cardboard boxes are stacked onto two pallets, one for each format, regarding the carton formats and their pallet patterns. Depending on the carton format, additional intermediate layers are taken from a third pallet space and placed onto the applicable carton layer. The pallet exchange happens via a safed area an with a light grid.

- in the paper and film industry

- primary/secondary packaging/palletizing

- packaging of winded products

- operations in connection with existing machines or as a comprehensive package

- packaging in connection with top load or side load boxes, box cases, etc.

- for single and multi-format operations

- automated format change

- automated gripper exchange

- component monitoring per RFID

- additional camera systems for quality controls

- additional product/box transport belts

- creation of assorted packages

- erection of box cases with hot glue or adhesive tape

- palletizing on several pallet types

- automatic pallet exchange

(project-specific)

- up to 80 winded rolls/min

(higher performance by technical adjustment possible)

- automatic removal of the coreless role directly from winding system

- primary packaging in top load box

- secondary packaging in carton tray with automatic bottom

- erection and loading with a robot and gripper

- palletizing on Euro- pallets

- maximum compact design

- intermediate layers

- for 2 different formats throughout at the same time

Our life is technology.

We will be happy to assist you.

Goldfuß engineering GmbH

Am Bangraben 12

72336 Balingen, Germany

Phone: + 49 [0] 7433 / 996599-0

Fax: +49 [0] 7433 / 996599-50

Email: kontakt@goldfuss-engineering.com